Being supported by an highly developed and specialist IT team, we could provide technical support on pre-sales & after-sales assistance for Professional Factory for China Supply High Quality Square and Round Ductile Cast Iron Drain Grating and Manhole Cover, We respect your enquiry and it's our honor to work with each individual buddy around the world.

Being supported by an highly developed and specialist IT team, we could provide technical support on pre-sales & after-sales assistance for China Grill and Marine Manhole Covers, To meet the requirements of personal customers for each bit more perfect service and stable quality goods. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

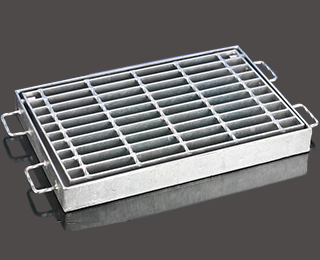

GT Trench Cover

1.GT trench cover suitable for all thoes roads, of which are not crowded, excluding highway. Avoiding the danger aring from unclosing, so screw should be used for fixing.

2.JGxxx/30/100 generally adopted, & other types of gratings should also be available. The grating with 50mm of cross bar suitable for thoes trench covers used in public place. If the serrated & the I-bar needed, it should be subject to final decision made by suppiler & buyer.

Learn Steel Grating

|

Steel Grating Standard |

Steel Material Standard | Hot galvanizing Standard |

| China: YB/T4001.1-2007 | China: GB700-2006 | China: GB/T13912-2002 |

| U.S.A: ANSI/NAAMM | U.S.A: ASTM(A36) | U.S.A: ASTM(A123) |

| U.K: BS4592 | U.K: BS4360(43A) | U.K: BS729 |

| Australia: AS1657 | Australia: AS3679 | Australia: AS1650 |

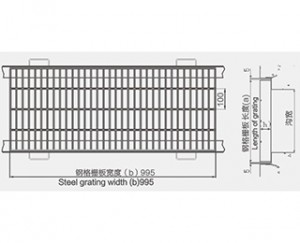

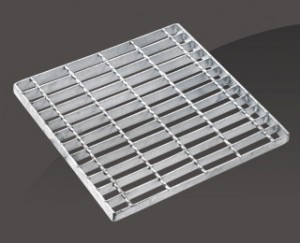

1. Bearing bar pitches may be 12.5 to 15, 20, 30,32.5,34.3, 40,60mm,of which 30mm & 40mm are recommended.

2. Cross bar pitches may be 38,50,60, to 100mm, of which 50mm & 100mm are recommended.

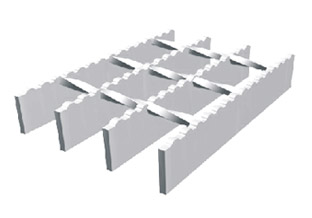

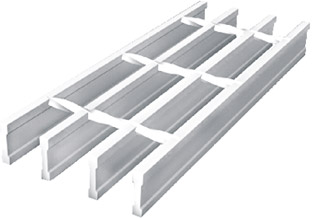

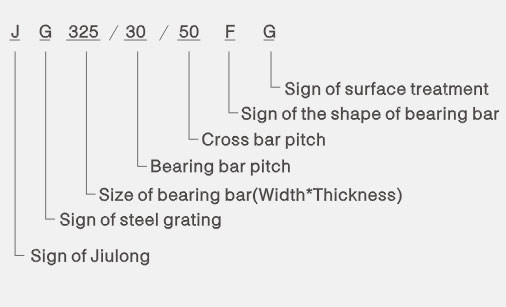

3. Sign of the shape of bearing bars. F - Plain style (may be omitted in the symbol of steel grating); S - Serrated style; I – I-shape style

4. Sign of surface treatment. G - Hot galvanizing (may be omitted in the symbol of steel grating); P - Painted; U – untreated

FIELDS OF APPLICATION :

1. Light chemical industry/Petro-chemistry/Machinery industry/Textile chemistry/Port engineering

2.Oil and grease chemistry/Agriculture husbandry/Horticulture/Steel industry/Waste disposale

3.Food processing/Aquatic breeding/Fertiliazer industry/Phamaceutical industry/Parking lots

4.Cement plants/Oil refinery/Mining and refinery/Power plants/Public utilties

5.Marine engineering/Shipbuilding/Construction material industry/Defense projects/Airport projects

6.Water plants/Sewage disposal/Paper and pulp industry/Construction industry/Transportation industry/Automotive industry

COMMON USES OF GRATING :

Flooring Catwalks Mezzanines/decking Stair tread Fencing

Vault bin floors Ramps Docks Trench covers Window and machinery safe guards

Entilation screens Storage racks Suspended ceiling Drainage pit cover Wash racks

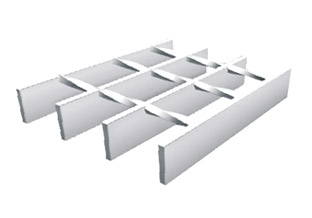

Type of Steel Grating

Comparison of Feature: