With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and progress, we are going to build a prosperous future together with your esteemed company for Ordinary Discount STEEL GRATING COVER WALKWAY COVER DRAIN COVER, Our closing purpose is "To try the most beneficial, To generally be the Best". Be sure to sense free of charge to get hold of with us if you have any prerequisites.

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and progress, we are going to build a prosperous future together with your esteemed company for , Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

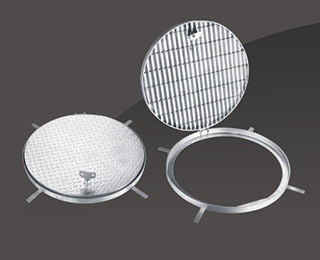

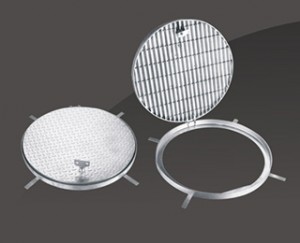

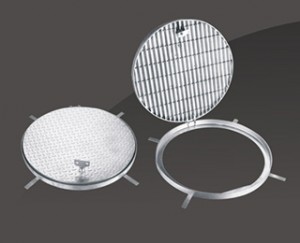

Dratnage Pit / Trench Cover

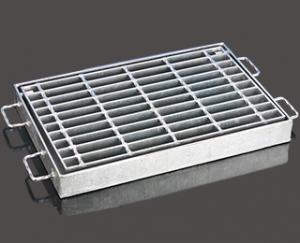

1. Grating trench cover used in walkway, carriageway, courtyard or other constructions. Used as cover for drainage trench, wireway, subway, air pit, etc. Hot-dip-galvanizing for surface treatment.

2. Grating trench cover composed by fixed fram & removable grating cover. It can be noted as GT & GU in terms of their different structures.

3. Grating pit cover used in catch basin, sand sediment trap, draining well, & sink hole for road, park & other civil projects. It’s generally designed as the evertile & its start-stop angle is 110°. The grating with pin joint is not only good to guard against theft but also simplify the construction procedure.

Class of Loading for Drainage Trench/Pit Cover

|

Class of Load |

Fully Laden(kg) |

Back Single-wheel Load(KN) |

Wheel-pressure Area a×b (mm2) |

|

T-25 |

25,000 |

100 |

200×500 |

|

T-20 |

20,000 |

80 |

200×500 |

|

T-14 |

14,000 |

56 |

200×500 |

|

T-6 |

6,000 |

24 |

200×240 |

|

T-2 |

2,000 |

8 |

200×160 |

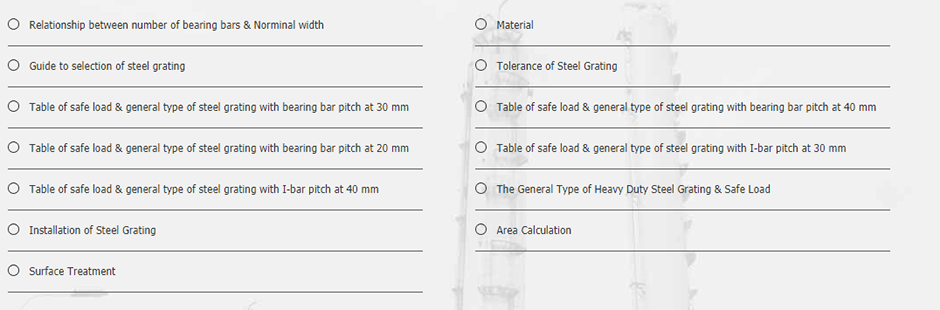

Learn Steel Grating

|

Steel Grating Standard |

Steel Material Standard | Hot galvanizing Standard |

| China: YB/T4001.1-2007 | China: GB700-2006 | China: GB/T13912-2002 |

| U.S.A: ANSI/NAAMM | U.S.A: ASTM(A36) | U.S.A: ASTM(A123) |

| U.K: BS4592 | U.K: BS4360(43A) | U.K: BS729 |

| Australia: AS1657 | Australia: AS3679 | Australia: AS1650 |

1. Bearing bar pitches may be 12.5 to 15, 20, 30,32.5,34.3, 40,60mm,of which 30mm & 40mm are recommended.

2. Cross bar pitches may be 38,50,60, to 100mm, of which 50mm & 100mm are recommended.

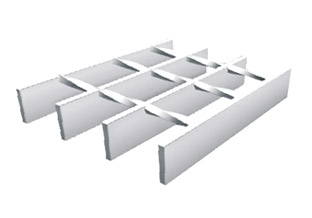

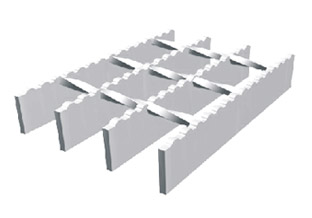

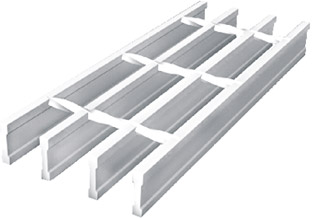

3. Sign of the shape of bearing bars. F - Plain style (may be omitted in the symbol of steel grating); S - Serrated style; I – I-shape style

4. Sign of surface treatment. G - Hot galvanizing (may be omitted in the symbol of steel grating); P - Painted; U – untreated

FIELDS OF APPLICATION :

1. Light chemical industry/Petro-chemistry/Machinery industry/Textile chemistry/Port engineering

2.Oil and grease chemistry/Agriculture husbandry/Horticulture/Steel industry/Waste disposale

3.Food processing/Aquatic breeding/Fertiliazer industry/Phamaceutical industry/Parking lots

4.Cement plants/Oil refinery/Mining and refinery/Power plants/Public utilties

5.Marine engineering/Shipbuilding/Construction material industry/Defense projects/Airport projects

6.Water plants/Sewage disposal/Paper and pulp industry/Construction industry/Transportation industry/Automotive industry

COMMON USES OF GRATING :

Flooring Catwalks Mezzanines/decking Stair tread Fencing

Vault bin floors Ramps Docks Trench covers Window and machinery safe guards

Entilation screens Storage racks Suspended ceiling Drainage pit cover Wash racks

Type of Steel Grating

Comparison of Feature:

-

Discountable price China Galvanized Heavy Duty ...

-

China Manufacturer for China Cheap Carbon Steel...

-

Hot Selling for China Jiulong Compound Steel Gr...

-

Professional Factory for China Supply High Qual...

-

Factory Customized Aluminum Expanded Metal Mesh...

-

Wholesale ODM China Newest Trampoline Park of C...