With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for OEM Manufacturer China Serrated Steel Grating-Drainage Cover, For high-quality gas welding & cutting equipment supplied on time and at the right value, you can count on organization name.

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for China Steel Grid, Construction Material, In the increasingly competitive market, With sincere service high quality solutions and well-deserved reputation, we always offer you customers support on merchandise and techniques to achieve long-term cooperation. Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we'll become long-term partners.

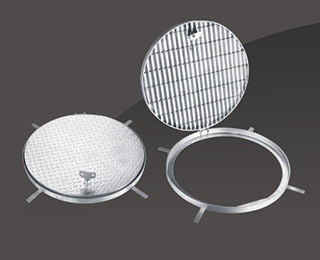

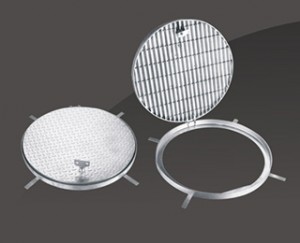

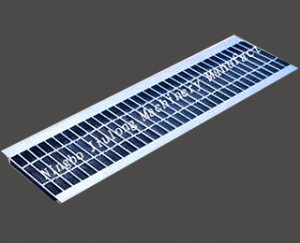

Dratnage Pit / Trench Cover

1. Grating trench cover used in walkway, carriageway, courtyard or other constructions. Used as cover for drainage trench, wireway, subway, air pit, etc. Hot-dip-galvanizing for surface treatment.

2. Grating trench cover composed by fixed fram & removable grating cover. It can be noted as GT & GU in terms of their different structures.

3. Grating pit cover used in catch basin, sand sediment trap, draining well, & sink hole for road, park & other civil projects. It’s generally designed as the evertile & its start-stop angle is 110°. The grating with pin joint is not only good to guard against theft but also simplify the construction procedure.

Class of Loading for Drainage Trench/Pit Cover

|

Class of Load |

Fully Laden(kg) |

Back Single-wheel Load(KN) |

Wheel-pressure Area a×b (mm2) |

|

T-25 |

25,000 |

100 |

200×500 |

|

T-20 |

20,000 |

80 |

200×500 |

|

T-14 |

14,000 |

56 |

200×500 |

|

T-6 |

6,000 |

24 |

200×240 |

|

T-2 |

2,000 |

8 |

200×160 |

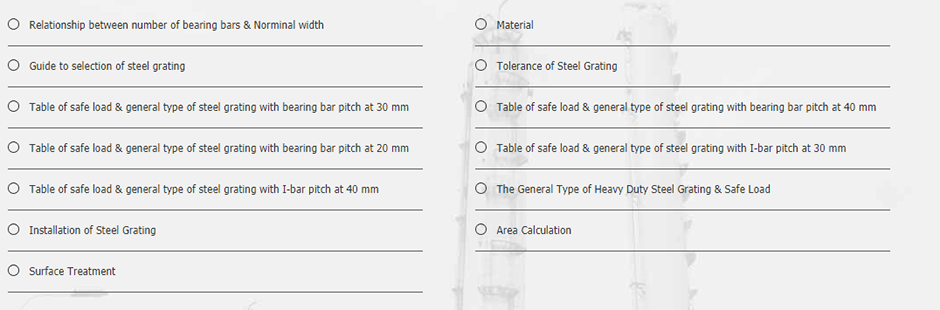

Learn Steel Grating

|

Steel Grating Standard |

Steel Material Standard | Hot galvanizing Standard |

| China: YB/T4001.1-2007 | China: GB700-2006 | China: GB/T13912-2002 |

| U.S.A: ANSI/NAAMM | U.S.A: ASTM(A36) | U.S.A: ASTM(A123) |

| U.K: BS4592 | U.K: BS4360(43A) | U.K: BS729 |

| Australia: AS1657 | Australia: AS3679 | Australia: AS1650 |

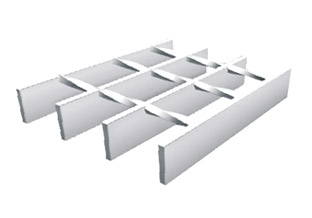

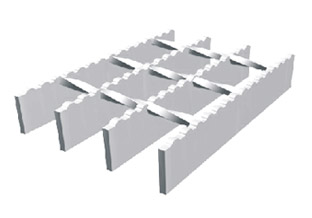

1. Bearing bar pitches may be 12.5 to 15, 20, 30,32.5,34.3, 40,60mm,of which 30mm & 40mm are recommended.

2. Cross bar pitches may be 38,50,60, to 100mm, of which 50mm & 100mm are recommended.

3. Sign of the shape of bearing bars. F - Plain style (may be omitted in the symbol of steel grating); S - Serrated style; I – I-shape style

4. Sign of surface treatment. G - Hot galvanizing (may be omitted in the symbol of steel grating); P - Painted; U – untreated

FIELDS OF APPLICATION :

1. Light chemical industry/Petro-chemistry/Machinery industry/Textile chemistry/Port engineering

2.Oil and grease chemistry/Agriculture husbandry/Horticulture/Steel industry/Waste disposale

3.Food processing/Aquatic breeding/Fertiliazer industry/Phamaceutical industry/Parking lots

4.Cement plants/Oil refinery/Mining and refinery/Power plants/Public utilties

5.Marine engineering/Shipbuilding/Construction material industry/Defense projects/Airport projects

6.Water plants/Sewage disposal/Paper and pulp industry/Construction industry/Transportation industry/Automotive industry

COMMON USES OF GRATING :

Flooring Catwalks Mezzanines/decking Stair tread Fencing

Vault bin floors Ramps Docks Trench covers Window and machinery safe guards

Entilation screens Storage racks Suspended ceiling Drainage pit cover Wash racks

Type of Steel Grating

Comparison of Feature:

-

18 Years Factory Hot DIP Galvanized Ditch Grate...

-

Hot Selling for China Jiulong Compound Steel Gr...

-

2019 New Style China Stair Nosing/ Anti-Slip Fl...

-

OEM/ODM Factory China Quality Galvanized Steel ...

-

Big Discount China Heavy Duty Hot DIP Galvanize...

-

Hot Selling for China Jiulong Compound Steel Gr...