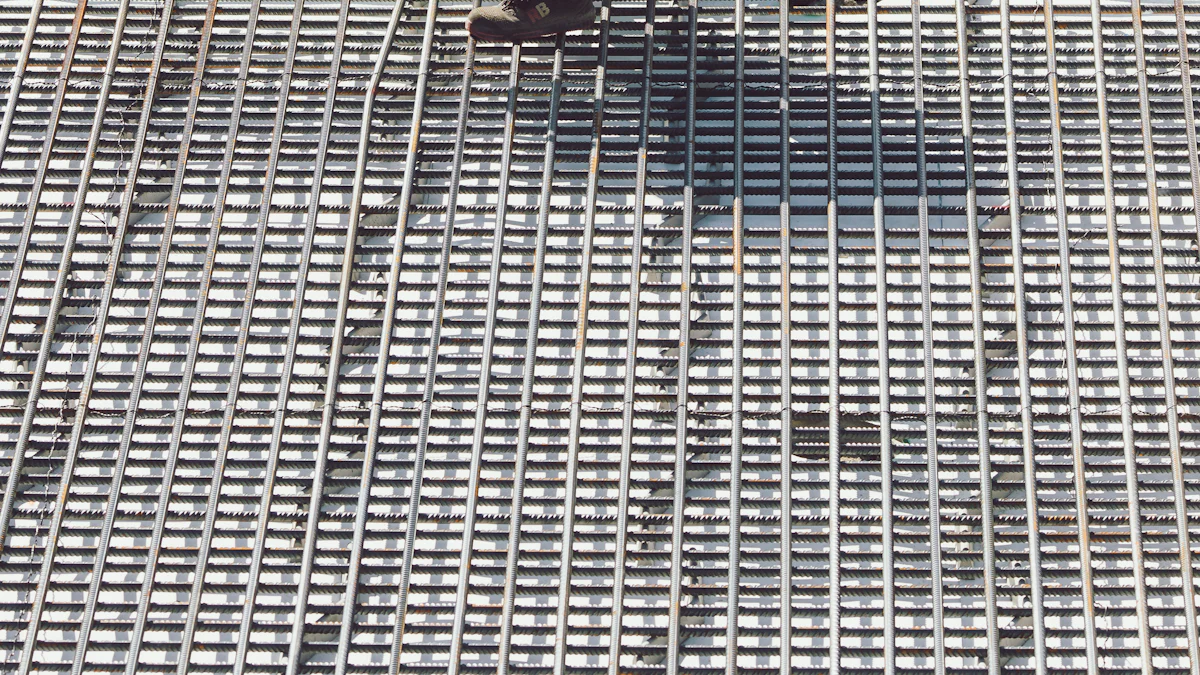

I’ve seen stainless steel grating transform industries with its unmatched durability and corrosion resistance. This material, crafted by welding bearing bars and crossbars, offers exceptional strength and load-bearing capacity. Stainless steel’s unique alloy composition, enriched with chromium, forms a protective layer that resists rust and corrosion. This makes it ideal for environments exposed to moisture, chemicals, or salt.

The global demand for stainless steel grating continues to rise. Projections show the market growing from $25.45 billion in 2024 to $52.6 billion by 2031, driven by its versatility and advancements in industrial applications. With over a decade of expertise in producing pressed welded steel grating, our company has supplied durable solutions for countless engineering projects.

Key Takeaways

- Stainless steel grating is tough and long-lasting. It works well for heavy loads in factories.

- It does not rust easily, so it lasts longer in rough conditions. This means fewer replacements are needed.

- Stainless steel grating needs little care. It saves time, money, and keeps busy areas safe.

Key Features and Benefits of Stainless Steel Grating

Durability and Strength

I’ve always been impressed by the mechanical properties of stainless steel grating. Its exceptional strength allows it to support heavy loads, making it ideal for high-traffic areas or industrial settings with heavy machinery. Unlike other materials, stainless steel has a high tensile strength, meaning it can endure significant pressure without deforming. This robustness ensures the grating remains intact even in challenging environments, reducing the need for frequent replacements. Over the years, my company has supplied pressed welded steel grating for projects requiring superior durability, and the results have consistently exceeded expectations.

Corrosion Resistance

Stainless steel grating stands out for its ability to resist corrosion. Its chromium content forms a protective oxide layer, shielding it from rust and degradation. This makes it perfect for marine environments, where salty air and humidity quickly corrode traditional materials. In industrial facilities, stainless steel withstands exposure to harsh chemicals and extreme temperatures. I’ve seen it perform exceptionally well in coastal installations and chemical plants, maintaining its integrity and appearance over time.

Low Maintenance and Longevity

One of the reasons I recommend stainless steel grating is its low maintenance requirements. Regular cleaning and inspections are usually sufficient to keep it in top condition. Proper drainage minimizes water exposure, while occasional degreasing ensures non-slip surfaces. Compared to other materials, stainless steel requires fewer repairs and replacements, offering long-term cost savings. Its longevity makes it a reliable choice for projects where durability is critical.

Versatility and Aesthetic Appeal

Stainless steel grating combines functionality with visual appeal. Its sleek, modern design enhances the aesthetics of architectural projects, from flooring and facades to pools and fountains. I’ve worked on projects where its reflective surface added elegance to public spaces, blending seamlessly with various architectural styles. Its customizability allows it to meet specific design and safety requirements, making it a versatile solution for both industrial and decorative applications.

Types of Stainless Steel Grating

Welded Stainless Steel Grating

Welded stainless steel grating is a powerhouse of strength and durability. I’ve seen it perform exceptionally well in industrial settings where heavy loads and high traffic are common. This type of grating is manufactured by resistance welding the bearing bars and crossbars at their intersections. The result is a robust structure capable of withstanding significant pressure without deformation.

| Advantage/Disadvantage | Description |

|---|---|

| Durability and Strength | Handles heavy loads, making it ideal for industrial and high-traffic areas. |

| Corrosion Resistance | Resists rust and corrosion, even in harsh environments. |

| Low Maintenance | Requires minimal upkeep, reducing long-term costs. |

| Safety Features | Non-slip surfaces and excellent drainage improve safety. |

| Aesthetic Appeal | Adds a modern, clean look to architectural designs. |

| Eco-Friendly | Fully recyclable, contributing to sustainability. |

However, welded grating has a higher initial cost and is heavier than alternatives, which can complicate installation. Despite these drawbacks, its reliability makes it a preferred choice for demanding applications.

Press-Locked Stainless Steel Grating

Press-locked stainless steel grating offers a sleek and lightweight alternative. This type is created by interlocking bearing bars and crossbars under high pressure. The process produces a visually appealing grating that balances strength and aesthetics. I often recommend press-locked grating for architectural projects where design matters as much as functionality.

Its applications include:

- Building facades

- Decorative installations

- Flooring and walkways requiring a polished appearance

- Sunscreens, grilles, and infill panels

While it may not match the load-bearing capacity of welded grating, its lightweight design and customizability make it ideal for pedestrian walkways and platforms.

Drain Grating and Specialty Grating

Drain grating and specialty grating cater to specific needs. Drain grating, for instance, is essential for managing water flow in areas like parking lots, industrial facilities, and public spaces. I’ve seen it used effectively to prevent water pooling and ensure safety.

Specialty grating, on the other hand, is tailored for unique applications. Whether it’s for chemical plants, food processing facilities, or decorative purposes, these gratings are designed to meet precise requirements. Their versatility and adaptability make them indispensable in projects demanding customized solutions.

The company I work with has over a decade of experience producing pressed welded steel grating. Our products have been used in countless engineering projects, from industrial platforms to architectural masterpieces.

Common Applications of Stainless Steel Grating

Industrial Applications

I’ve seen stainless steel grating excel in industrial environments due to its strength, durability, and safety features. Industries like chemical processing, power plants, and oil and gas rely on it for its ability to withstand harsh conditions. Its corrosion resistance makes it invaluable in offshore rigs and refineries, where exposure to saltwater is constant.

Here’s a breakdown of its industrial uses:

| Industry | Reason for Use |

|---|---|

| Chemical Processing Plants | Resistant to chemicals, ideal for harsh environments. |

| Power Plants | Withstands high temperatures and heavy loads. |

| Oil and Gas Industry | Corrosion-resistant, valuable in offshore rigs and refineries. |

| Food Processing Facilities | Hygienic properties, easy to clean, reduces contamination risk. |

| Public Infrastructure | Handles heavy traffic, offers safety features like non-slip surfaces. |

In my experience, stainless steel grating also enhances safety. Its non-slip surfaces and excellent drainage reduce slip hazards, while its high tensile strength ensures stability in elevated structures. These features make it a reliable choice for platforms, walkways, and mezzanines.

Commercial Applications

Stainless steel grating plays a vital role in commercial spaces. I’ve worked on projects where it was installed in high-traffic entryways, vestibules, and corporate office entrances. Its sleek design adds a modern touch while ensuring safety and durability.

| Commercial Space Type | Description |

|---|---|

| High-Traffic Entryways | Commonly used for entrances to manage foot traffic. |

| Commercial Vestibules | Provides safety and aesthetic appeal in entry areas. |

| Corporate Office Entrances | Enhances the entrance experience in corporate settings. |

In food processing facilities, its hygienic properties stand out. Stainless steel grating is easy to clean and resists contamination, making it ideal for maintaining strict hygiene standards. Public infrastructure projects, such as bridges and parking garages, also benefit from its durability and safety features.

Architectural and Decorative Uses

I’ve seen stainless steel grating transform architectural designs with its blend of functionality and aesthetics. It’s a popular choice for flooring, ventilation, and drainage in pools, fountains, and revolving doors. Its ability to handle high load capacities while integrating seamlessly with surrounding materials makes it indispensable in these applications.

The strength of stainless steel grating also supports elevated walkways, staircases, and ramps. Its high tensile strength ensures structural integrity, even under heavy pressure. I’ve worked on projects where its reflective surface added elegance to public spaces, proving its versatility in both decorative and functional roles.

With over a decade of experience in producing pressed welded steel grating, my company has supplied products for countless engineering projects. From industrial platforms to architectural masterpieces, our gratings deliver unmatched performance and reliability.

Stainless steel grating offers unmatched versatility and durability, making it indispensable across industries. Its corrosion resistance ensures longevity in harsh environments, while its recyclability supports sustainable practices. I’ve seen firsthand how its ability to withstand physical stress reduces maintenance and replacement costs, delivering long-term savings. For over a decade, my company has provided pressed welded steel grating for diverse engineering projects, consistently meeting safety and performance standards.

FAQ

What makes stainless steel grating better than other materials?

Its corrosion resistance, strength, and low maintenance make it superior. I’ve seen it outperform alternatives in durability, especially in harsh environments like chemical plants or coastal areas.

Can stainless steel grating be customized for specific projects?

Yes, it’s highly customizable. I’ve worked on projects where we tailored grating dimensions, patterns, and finishes to meet unique safety, load-bearing, or aesthetic requirements.

How long does stainless steel grating typically last?

With proper care, it lasts decades. I’ve seen installations remain functional and visually appealing for over 20 years, even in demanding industrial or marine environments.

Post time: Jan-16-2025