Sticking on the theory of "Super Quality, Satisfactory service" ,We have been striving to become a good company partner of you for Factory wholesale China Hot DIP Galvanized Trench Cover From Steel Grating, We've been self-confident that there will be considered a promising upcoming and we hope we could have long term cooperation with prospects from all over the environment.

Sticking on the theory of "Super Quality, Satisfactory service" ,We have been striving to become a good company partner of you for China Galvanized Trench Cover, Galvanized Steel Grating, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

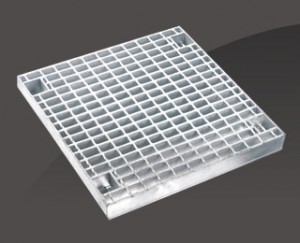

GU Trench Cover

Refer to most oral groove without edge made by concrete, it would be most simple & saving, so that it’s no need to make a special groove of trench.The angle steel is suggested to be built in the top edge of trench as the load is in the range between T-6 to T-14. The prefab building blocks of GU trench cover is also available for making the trench which can prevent dirty water to leak into the earth. But GU trench cover just suitable for side ditch when a car or truck need to cross it.

Class of Loading for Drainage Trench/Pit Cover

|

Class of Load |

Fully Laden(kg) |

Back Single-wheel Load(KN) |

Wheel-pressure Area a×b (mm2) |

|

T-25 |

25,000 |

100 |

200×500 |

|

T-20 |

20,000 |

80 |

200×500 |

|

T-14 |

14,000 |

56 |

200×500 |

|

T-6 |

6,000 |

24 |

200×240 |

|

T-2 |

2,000 |

8 |

200×160 |

Learn Steel Grating

|

Steel Grating Standard |

Steel Material Standard | Hot galvanizing Standard |

| China: YB/T4001.1-2007 | China: GB700-2006 | China: GB/T13912-2002 |

| U.S.A: ANSI/NAAMM | U.S.A: ASTM(A36) | U.S.A: ASTM(A123) |

| U.K: BS4592 | U.K: BS4360(43A) | U.K: BS729 |

| Australia: AS1657 | Australia: AS3679 | Australia: AS1650 |

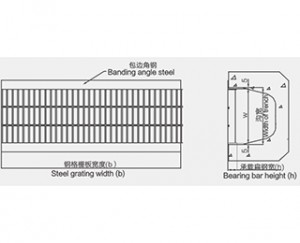

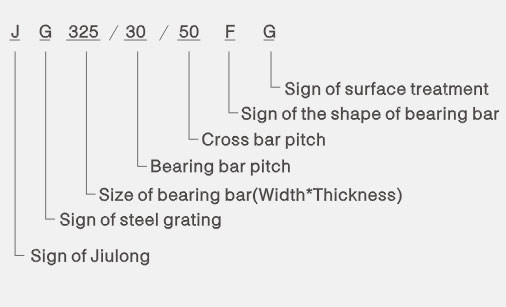

1. Bearing bar pitches may be 12.5 to 15, 20, 30,32.5,34.3, 40,60mm,of which 30mm & 40mm are recommended.

2. Cross bar pitches may be 38,50,60, to 100mm, of which 50mm & 100mm are recommended.

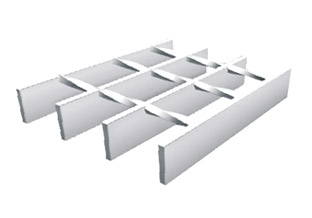

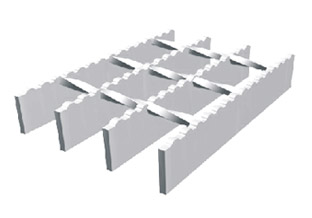

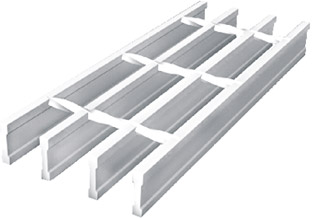

3. Sign of the shape of bearing bars. F - Plain style (may be omitted in the symbol of steel grating); S - Serrated style; I – I-shape style

4. Sign of surface treatment. G - Hot galvanizing (may be omitted in the symbol of steel grating); P - Painted; U – untreated

FIELDS OF APPLICATION :

1. Light chemical industry/Petro-chemistry/Machinery industry/Textile chemistry/Port engineering

2.Oil and grease chemistry/Agriculture husbandry/Horticulture/Steel industry/Waste disposale

3.Food processing/Aquatic breeding/Fertiliazer industry/Phamaceutical industry/Parking lots

4.Cement plants/Oil refinery/Mining and refinery/Power plants/Public utilties

5.Marine engineering/Shipbuilding/Construction material industry/Defense projects/Airport projects

6.Water plants/Sewage disposal/Paper and pulp industry/Construction industry/Transportation industry/Automotive industry

COMMON USES OF GRATING :

Flooring Catwalks Mezzanines/decking Stair tread Fencing

Vault bin floors Ramps Docks Trench covers Window and machinery safe guards

Entilation screens Storage racks Suspended ceiling Drainage pit cover Wash racks

Type of Steel Grating

Comparison of Feature: