We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for factory Outlets for China SMC Gully Grating with B125, We warmly welcome buddies from all walks of everyday living to hunt mutual cooperation and build a more brilliant and splendid tomorrow.

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for China Manhole Cover, Composite SMC, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good products and solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

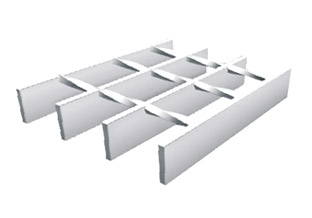

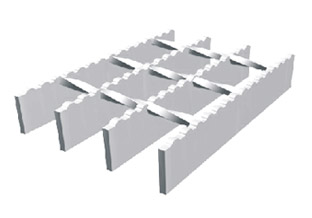

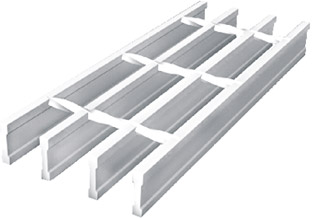

Compound Steel Grating

1. Compund steel grating is composed of chequered plate on sealed surface & steel grating with certain spanning capability.

2. Compound steel grating is formed of any type of steel grating and chequered plate in different thicknesses. The grating of JG323/40/100, JG253/30/100 or JG323/60/100 is generally used as support plate & the chequered plate with 3mm thickness is used as upper plate, while the plate of 4mm, 5mm or 6mm thickness may also be used based on customers’ requirements.

3. As thermal stress may produce shape distortion for compound steel grating after hot-dip galvaning treatment, especially when choosing large spacing grating, it’s not easy to make it smooth. So attention should be paid when choosing grating types.

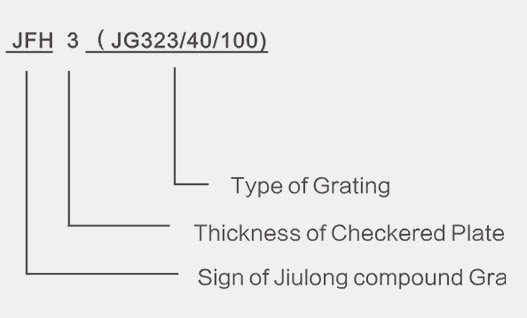

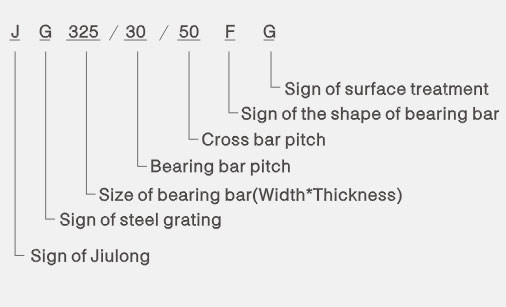

SIGN OF COMPOUND STEEL GRATING

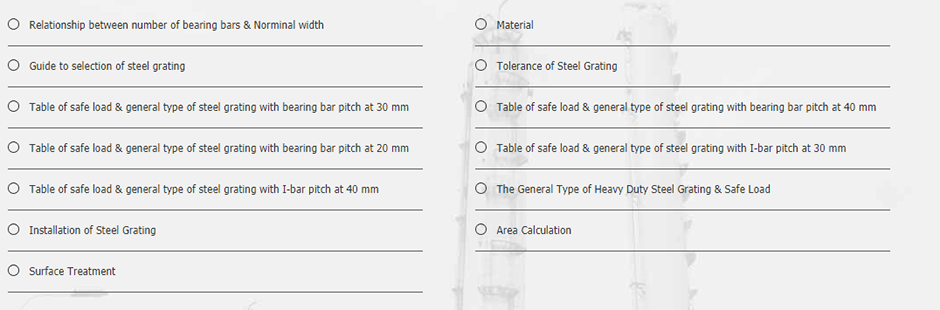

Learn Steel Grating

|

Steel Grating Standard |

Steel Material Standard | Hot galvanizing Standard |

| China: YB/T4001.1-2007 | China: GB700-2006 | China: GB/T13912-2002 |

| U.S.A: ANSI/NAAMM | U.S.A: ASTM(A36) | U.S.A: ASTM(A123) |

| U.K: BS4592 | U.K: BS4360(43A) | U.K: BS729 |

| Australia: AS1657 | Australia: AS3679 | Australia: AS1650 |

1. Bearing bar pitches may be 12.5 to 15, 20, 30,32.5,34.3, 40,60mm,of which 30mm & 40mm are recommended.

2. Cross bar pitches may be 38,50,60, to 100mm, of which 50mm & 100mm are recommended.

3. Sign of the shape of bearing bars. F - Plain style (may be omitted in the symbol of steel grating); S - Serrated style; I – I-shape style

4. Sign of surface treatment. G - Hot galvanizing (may be omitted in the symbol of steel grating); P - Painted; U – untreated

FIELDS OF APPLICATION :

1. Light chemical industry/Petro-chemistry/Machinery industry/Textile chemistry/Port engineering

2.Oil and grease chemistry/Agriculture husbandry/Horticulture/Steel industry/Waste disposale

3.Food processing/Aquatic breeding/Fertiliazer industry/Phamaceutical industry/Parking lots

4.Cement plants/Oil refinery/Mining and refinery/Power plants/Public utilties

5.Marine engineering/Shipbuilding/Construction material industry/Defense projects/Airport projects

6.Water plants/Sewage disposal/Paper and pulp industry/Construction industry/Transportation industry/Automotive industry

COMMON USES OF GRATING :

Flooring Catwalks Mezzanines/decking Stair tread Fencing

Vault bin floors Ramps Docks Trench covers Window and machinery safe guards

Entilation screens Storage racks Suspended ceiling Drainage pit cover Wash racks

Type of Steel Grating

Comparison of Feature:

-

18 Years Factory China Hot dipping galvanized s...

-

Bottom price China Customized Stainless/Carbon/...

-

OEM/ODM China China Wholesale Building Imperial...

-

Hot Selling for China Jiulong Compound Steel Gr...

-

Reasonable price China Floating Staircase/Solid...

-

Bottom price China Contemporary Queue Managers ...